Steel

Ferrite Balanced Alloy for All Steels Giving Super Strength

MF 100 All Steel

Freshly made to serve unknown composition steel, for maintenance industry and most dissimilar steels, Special flux coating to meet welder’s appeal with drastically reduced spatter, self-peeling slag joining and overlay in almost every position type repair.

TDS MSD

MF 105

Unique Low-Hydrogen type deposit for the most low, High Alloy steel. Decent arc stability on AC power sources which makes it more of a versatile LH type deposit, Excellent crack resistant quality, In some cases up-to 14 mm thick components without preheat.

TDS MSD

MF 107

MF 108

MF 12C

Low temperature , high strength , non-toxic cadmium free solid core silver soldering wire.

MF 12F

Non-toxic silver brazing wire specially design for clean environment applications, including food processing and medical institutions

MF 400

Universal Alloy for Hastelloy C, Nickel & Molybdenum. Deposits are rich in chromium, nickel and molybdenum

MF 401

Problem solver, Excellent for elevated temperature applications, also engineered for chemical resistant.

Stainless Steel including 316 L

MF 205

Unique electrode for good weldability, in moist and wet condition, Takes care of most chemical and fertiliser application, Serves well in food industry too.

MF 206

Finds application in most dairy equipments breweries, bottling plant for High corrosion repairs are most suited, Special niobium/titanium stabilised, This helps in reduced carbide precipitation.

MF 208 Root guard

weld 316Lpipes without costly shield gag, Finds excellent application in off shore rigs for sour gas pipe and tubing with increased ferrite content, takes care of (scc) stress corrosion cracking.

MF 208 Root guard

Brazing, Soldering filler rods

Cast Iron

Unique Low-Hydrogen type deposit for the most low, High Alloy steel.

MF 300

Very Useful Cast Iron in welding dirty cast iron components and oil-soaked types, Non machinable, but is excellent in color matching properties, A Good mechanical strength can also weld cast iron to steel, Gives variety of choice in application wise.

TDS MSDS

MF 301

Super strength non-cracking universal cast iron electrode is Originally a Nickel based type which takes care of most cast iron job repairs, Excellent elongation to prevent cracking while repairs.

MF 302

Surface contaminants burns are very easily processed because of the controlled arc transfer, Also prevents from overheating even with AC power sources to cover major repair shops, Holds a good ductile deposit with combined tensile strength.

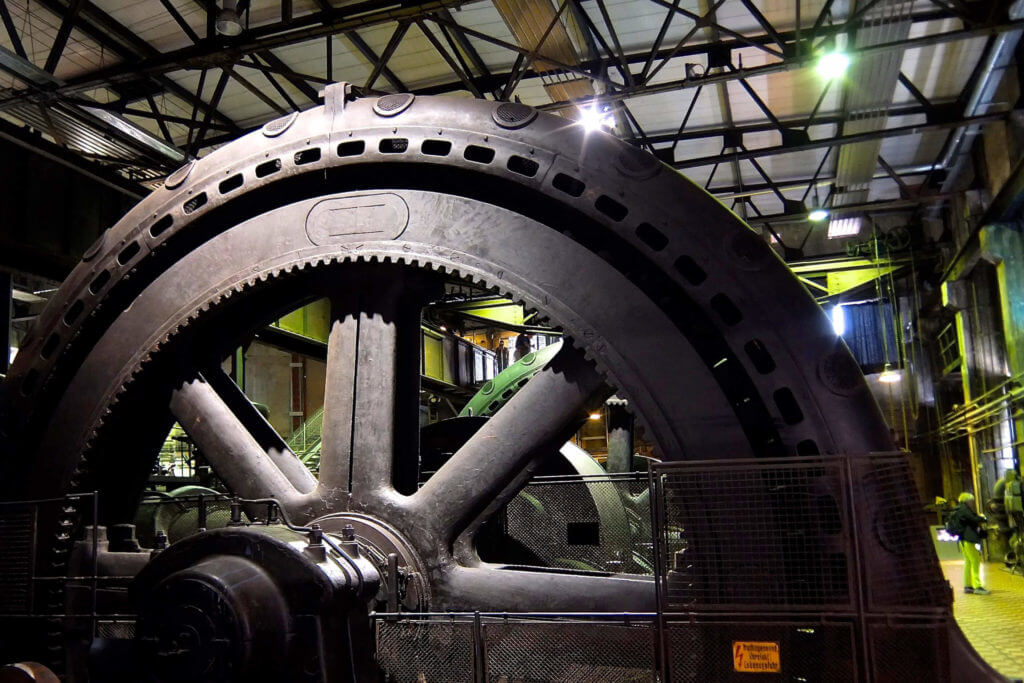

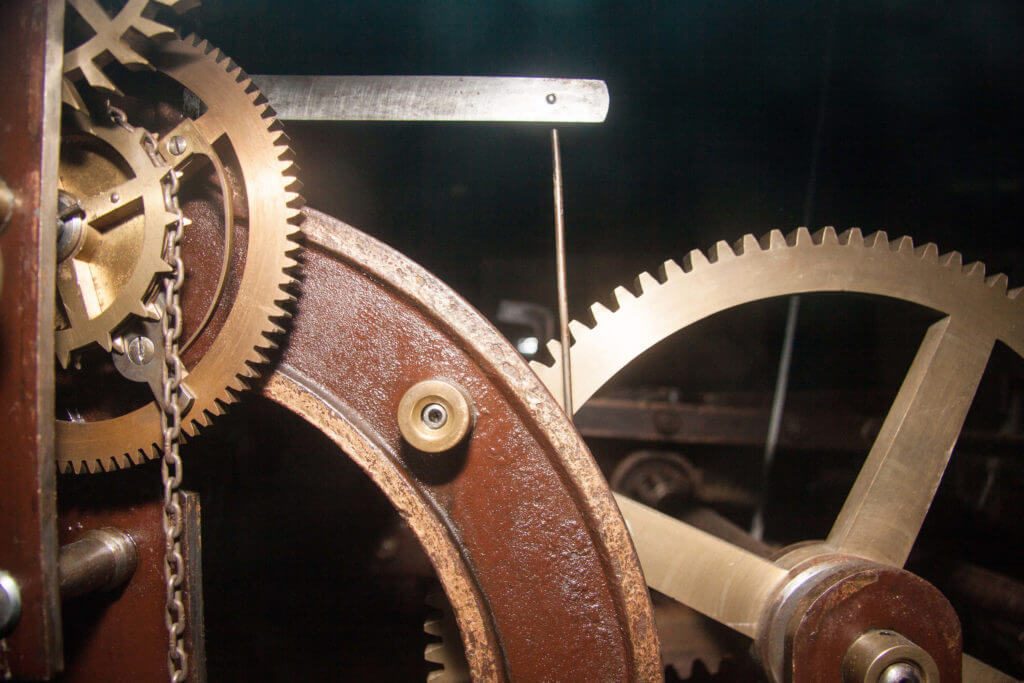

Hardfacing

Crusher rod with remarkable abrasion and good impact properties, Widely used in mining and heavy construction industry.

MF 600

Crusher rod with remarkable abrasion and good impact properties, Widely used in mining and heavy construction industry.

MF 602

Electrode to resist extreme shock and impact for joining Austenitic Manganese steel with work hardening properties.

MF 604

Chromium carbide in alloy steel matrix resisting extreme grinding and abrasion too,

Most mining equipment falls under product MF604.

MF 605

Excellent build up type HF electrode with good, work accurate properties, Used in application of high alloy and low steel with good cushioning effect, Also suitable in some cases for C45 Steel.

MF 606

High speed steel electrode mostly finds application on high speeds with both

tungsten and molybdenum type steel, Very prominent for repairs on damaged chipped worn out and also converting ordinary steel to make good cutting edge tools.

MF 607

All-purpose tool, die and mould steel hot and cold working for metal to metal, Covers most AISI–D2, (SKD-11), A2, S1, H13 type tools and in cases for emergencies as well on L6 tool steel too is mostly used in repairing, dies already in service too.

Hard Facing Wires

MF MIG MC 60

Self shielded metal cored wire finds application, In outdoor repairs saving time in situ jobs, It is a low alloy deposits welds pass over pass to increase productivity and save time, Finds bucket teeth, dragging buckets, gear teeth and so on, In mining industry, the deposit hardness is between 56 to 58 RC.

Aluminum

MF 500

Real emerging stuck electrode for the most general welding purposes because of it’s fluidity, Covers 6xxx, 5xxx, type alloys, Works more efficiently on DC + only.

MF 501

High strength based AL electrode with 12% silicon covers most 4xxx series of alumina jobs repairs, Good color matching properties combined with minimum spatter makes welder’s appeal for emergency repairs with fair slag removal too.

MF 50

Brazing Alloy for all types of Aluminum. Easy to apply at a lower temperature than base metal melting point.

MF 51

MF-51 low temperature solder for joining aluminum to other non ferrous and ferrous metal

Yellow metals

MF 704

Most marine repair falls under this product good for joining copper alloys with Nickel gives additional wear resistance deposits in cavities and has made easy and handy for the welders.

Chamfering & Gouging

Quick and efficient chamfering electrode

MF 800

Efficient cutting and chamfering electrode to cut and bevel in most melts including SS, Aluminium and copper as well.

Welding Aids

A dramatic solution towards eliminating long hours of hard surfacing.

MF 900

Heat absorbing and dissipating compound, Allowed to be safely used on metals and glass to avoid excessive heat from flame temperature build up to control distortion.

MF 904

Resin based compound based on Epoxy system, It is filled with bronze for most general purposes, To bear in mind is that this cannot be used in Food industry, But is most suited for the ferrous, non-ferrous and non-metals too as a quick repair compound on emergency basis.

MF 904

TIG - MIG

A very high deposition manganese alloy wire for severe impact.

MF MIG FC 62

Self shielded flux cored wire (75% argon-25% co2). Mixtures extreme shock and impact used in joining austenitic Manganese steel work hardening type, finds application reclamation of rail track points and crossings and other rail related repairs.

MF MIG FC 65

Self-shielded metal core wire, Having a wide usage of repairs in outdoor jobs, used as an excellent build up for (economy) purpose, Good cushioning effect in hardness up-to 25 to 30 RC, Excellent for metal to metal application.

MF TIG 208FC

A dramatic solution towards eliminating long hours of hard surfacing. A very special TIG wire that, eliminates the expense & down time associated with purging pipes with inert backing gasses